Northtech, NT 820HC-505032 Double Surface Planer

Northtech, NT 820HC-505032 Double Surface Planer

Contact us for price

Location:Dundee, NY

Description

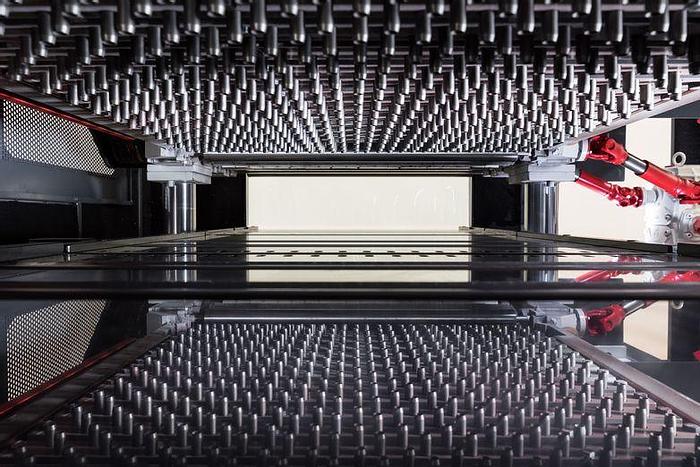

The NT 820HC is our 32″ width double surfacer with over 6″ thickness capability. Double surfacers, some times referred to as 2 sided planers are used to size the thickness of wood and other dense materials such as plastic. The top and bottom helical cutter head uses two sided 30x12x2.5 carbide insert cutters for a moulder smooth finish, even with heavy stock removal. The powered top and bottom feed system is designed with (7) rollers integrated in the chrome bed and a spring loaded carpet spike infeed with a gearbox connected carden shaft drive. The carden shaft drive delivers a slack free feed with out the common chain adjustments. The jointer table infeed and overhead spring loaded carpet spike system allows this machine to not only size the thickness, but also straighten warped or crooked material. The top head is easily accessible for tooling changes by removing the dust hood and the bottom head pulls out of the machine completely in just a couple minutes for full access. The upper assembly is supported by a (4) column slide system that provides precision thickness sizing across the entire width and has digital thickness positioning control. Northtech Double surfacers are available in 16″-52″ working widths with up to a 24″ working thickness and can be offered with a safety/sound enclosure.

CUTTERHEADS 50 HP Top, 50 HP Bottom Dual (8) Row Helical Cutterhead with double sided 30 x 12 x 2.5mm inserts 5000 RPM solid steel cutterheads with Class 7 NSK bearings PRODUCT DIMENSIONS Working width 820mm (32”) 13” min working length Thickness range (3/8” - 8”) FEED SYSTEM 10HP + 15HP inverter feed motor Elevation motor: 2HP Carpet feeding spike system with 1500 spikes Feed speed 30-80 FPM FEATURES Digital control panel with 3 oversized inverter feed control amp meters Chrome bed plate Patented 4 column lifting system Carpet feeding spike system Cardan shaft drive system 80 FPM maximum feed speed Amperage requirement at 161 @ 460V; 322 @ 230V (4) 6” dust ports requiring 981 CFM @ each point of extraction UL/CE Certified electrical components Lubricating system Includes operator’s manual and parts book Machine dimensions: 115” L x 88” W x 70” H Packing dimensions: 122”L x 90”W x 77”H Machine gross / net weight: 15,433 lbs. / 16,535 lbs One year parts warranty All machines are tested stateside prior to shipment providing trouble-free start up.

Specifications

| Manufacturer | Northtech |

| Model | NT-820HC |

| Condition | New |

| Stock Number | NT 820HC-505032 |

| VOLTAGE, FREQUENCY | 230/460 Volt 60HZ |

| PHASE | 3 Phase |

| FEED SYSTEM | Carpet Feed / Powered Rollers |

| DRIVE SYSTEM | Cardan Shaft Drive System |

| VARIABLE FEED SPEED | Inverter Controlled |

| ELEVATION HP | 2 HP |

| APPROVED ELECTRICAL PARTS | CE Approved Components |

| DUAL VOLTAGE MOTORS | 230/460 Volt |

| CONTROL VOLTAGE | 110 Volt |

| PROGRAMABLE | Elevation |

| ADJUSTABLE OPERATOR PANEL | Adjustable Operator Panel |

| HEAD TYPE | Dynamically Balanced Helical Head |

| CUTTER HEAD MATERIAL | Alloy Steel |

| REAR E STOP | Push Button |

| FRAME CONSTRUCTION | Cast Construction |

| DECIBEL RATING | 75 dB |